การค้นหาผลิตภัณฑ์

ภาษา

ออกจากเมนู

คู่มือเครื่องนึ่งฆ่าเชื้อแบบ Autoclave Class B: การเลือก การใช้ และการตรวจสอบความถูกต้อง

โพสต์โดย ผู้ดูแลระบบ | 04 Jan

What an Autoclave Class B Sterilizer Is (and Why It’s Different)

An autoclave Class B sterilizer is a pre-vacuum steam sterilizer designed to handle the most challenging small-load scenarios—especially wrapped packs, porous loads, and hollow/lumen instruments . In practical terms, “Class B” refers to fractionated pre-vacuum air removal (multiple vacuum pulses), followed by saturated steam exposure and post-vacuum drying. This combination is intended to eliminate air pockets and improve steam penetration into complex devices.

Industry explanations of Class B performance commonly describe the pre-vacuum phase as removing more than 99% of chamber air through repeated pulses, improving penetration into the “deepest point of the load,” and then using vacuum again for drying after sterilization.

For clinics and laboratories that process mixed instrument sets (solid hollow, wrapped unwrapped), a Class B tabletop unit can simplify SOPs by reducing the number of “exceptions” in your load types. If you are evaluating a tabletop solution, you can review a representative configuration here: Class B table-top pulse vacuum steam sterilizer .

Which Loads Justify Moving to a Class B Autoclave

In procurement discussions, we recommend starting with your “hardest-to-sterilize” item, not your easiest. If your daily workload includes any of the following, a Class B sterilizer is typically the most operationally robust option:

- Hollow/lumen instruments (e.g., dental handpieces, suction tips, cannulated instruments, inset pipes).

- Wrapped cassettes or packs that must remain sterile until point-of-use.

- Porous loads (e.g., textile packs, certain dressings) where trapped air can block steam contact.

- Mixed loads where “one cycle for everything” reduces training burden and mistakes.

Why this matters: steam sterilization is contact-dependent. If residual air remains trapped in lumens or within packaging, steam cannot reliably reach all internal surfaces. The defining Class B advantage is its active air removal and drying via a vacuum pump.

| Load type | Primary risk mechanism | Why Class B helps |

|---|---|---|

| Hollow/lumen items | Air pockets block steam entry | Fractionated pre-vacuum improves air removal; Helix/PCD supports verification |

| Wrapped packs | Limited diffusion through packaging | Enhanced penetration post-vacuum drying reduces wet packs |

| Porous/textile loads | Residual air and retained moisture | Bowie-Dick style air-removal testing aligns with pre-vacuum performance checks |

Specification Checklist for Buying a Class B Tabletop Sterilizer

A Class B autoclave is a system: vacuum pump performance, steam generation stability, drying effectiveness, controls, and documentation all affect outcomes. For purchasing teams, we recommend verifying the following items as “must-have” for daily clinical use (especially when wrapped and hollow loads are routine):

Air removal and vacuum integrity

- Target vacuum level and repeatability (example capability: -0.8 bar vacuum data for a tabletop Class B configuration).

- Built-in vacuum/leak test program so staff can quickly confirm chamber tightness before starting production loads.

- Support for Bowie-Dick/Helix type testing (air removal steam penetration verification).

Sterilization parameters and thermal stability

- Cycle temperature coverage (common benchmark cycle includes 134℃ ; some applications use lower-temperature “delicate” cycles, depending on validated load limits).

- Uniformity indicators such as heat average ≤±1℃ for stable exposure conditions.

- Independent steam generator design can improve responsiveness and reduce dependence on external steam supply for tabletop environments.

Drying, traceability, and human factors

- Post-vacuum drying performance (wet packs should be treated as a process failure for wrapped storage).

- Cycle records (printer or digital export) to support audits and internal QA; a built-in mini printer is a practical solution for many sites.

- Clear UI and error-proofing (LCD status, touch keys, alarms) to reduce operator mistakes.

If you are standardizing multiple departments, it can be useful to shortlist within one product family for consistent training and spares. For example, you can review our broader tabletop portfolio here: table top steam sterilizer manufacturers .

Installation and Daily Operation Practices That Protect Sterility

Even the best autoclave Class B sterilizer can underperform if the workflow is inconsistent. The objective is to control water quality, loading, packaging, and cooling so the sterilization and drying phases can do their job predictably.

A practical daily workflow (tabletop clinics and labs)

- Confirm water quality (use purified/deionized water per your SOP) and verify the water system status before production cycles.

- Run the required start-of-day test cycle(s) (e.g., air-removal test such as Bowie-Dick/Helix where applicable, plus vacuum/leak test if part of your protocol). Load by “steam access,” not by convenience: avoid stacking pouches tightly; keep lumen openings oriented to support air evacuation and steam entry.

- Select the cycle validated for the load: many Class B workflows use a high-temperature cycle reaching 134℃ for standard metal/glass loads; delicate materials may require lower temperature and longer exposure as defined by your validated program.

- Allow post-cycle cooling and drying completion before handling packages; premature handling increases the chance of wicking and recontamination.

- Store wrapped items correctly (clean, dry, protected) and maintain traceability records for each lot.

From an engineering standpoint, you should also confirm the unit’s safety interlocks (door lock, pressure lock, over-temperature/over-pressure protection) are active and tested according to the manufacturer’s maintenance schedule.

Routine Monitoring: Bowie-Dick, Helix, Vacuum Tests, and Documentation

For pre-vacuum steam sterilizers, routine monitoring is not a “nice-to-have”—it is how you demonstrate that air removal and steam penetration are consistently achieved. Bowie-Dick type testing is widely described as an air-removal performance evaluation for pre-vacuum sterilizers.

For hollow instruments, Helix-type process challenge devices are commonly used to simulate difficult lumen conditions and evaluate air removal and steam penetration for type-B sterilizers.

A monitoring cadence many facilities adopt

- Daily (before loads): Bowie-Dick/Helix as required by your SOP; vacuum/leak test if specified; review any alarms or deviations.

- Each cycle: place chemical indicators per policy; verify cycle printout/data record matches the validated program (time/temperature/pressure).

- Weekly or per policy: biological indicator testing (especially after repairs, relocation, or major load changes).

- Planned maintenance: gasket inspection, chamber cleaning, filter checks, vacuum system checks, and calibration verification as applicable.

In real audits, traceability becomes the differentiator. A built-in printer (or digital log) reduces transcription errors and supports faster investigations if a load is quarantined.

Troubleshooting Outcomes That Matter: Wet Packs, Failed Tests, and Cycle Deviations

When customers report “sterilization problems,” the root cause is often a repeatable pattern: loading, packaging, water quality, or vacuum integrity. The table below is a practical troubleshooting view aligned to Class B workflows (pre-vacuum drying).

| Symptom | Most common cause | Corrective action |

|---|---|---|

| Wet packs after cycle | Overloading, poor pouch spacing, inadequate drying phase completion | Reduce load density; ensure correct cycle; do not handle until dry and cooled |

| Bowie-Dick/air-removal test failure | Vacuum leak, blocked drain/filter, vacuum pump performance issue | Run vacuum/leak test; inspect gasket; follow service protocol before processing loads |

| Inconsistent cycle records | Operator settings drift; sensor/calibration deviation | Lock validated programs; schedule calibration/verification; retrain operators |

| Frequent low-water alarms or scaling | Improper water quality; tank management issues | Use purified water; clean reservoirs; follow maintenance interval; verify tank separation design if equipped |

If you are repeatedly troubleshooting the same symptom, treat it as a process control problem: standardize loading diagrams, limit “custom cycles,” and make test results visible to the team.

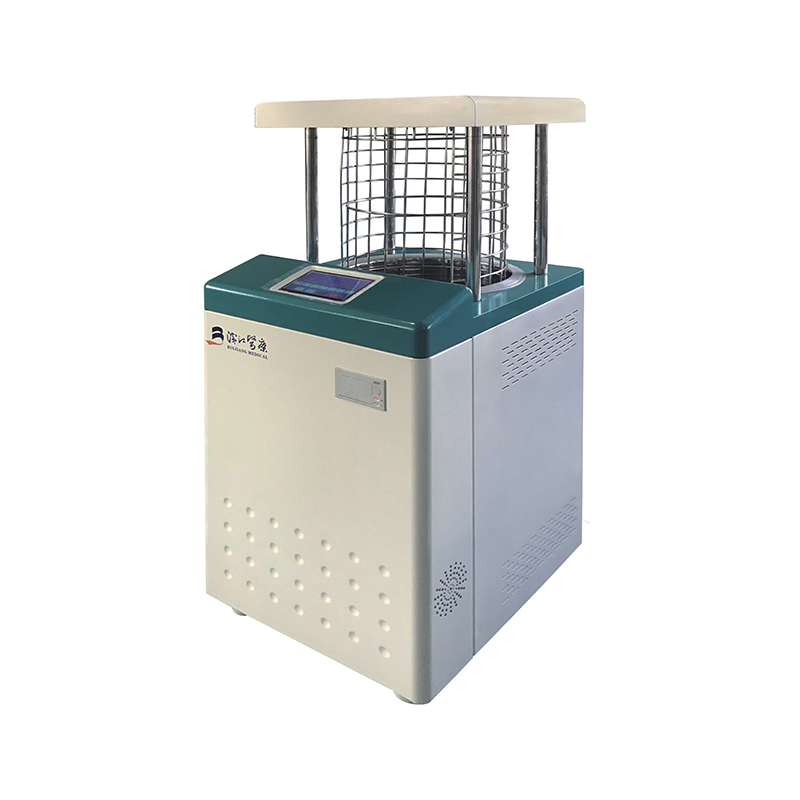

Example Technical Data: Class B Tabletop Pulse Vacuum Steam Sterilizer

When stakeholders ask for “Class B,” they often also need to align on capacity, utilities, and documentation. Below is an example specification snapshot from our Class B tabletop pulse vacuum steam sterilizer line (two common chamber sizes), which includes features such as three times vacuum and drying , -0.8 bar vacuum capability, Bowie&Dick support, vacuum testing, an independent steam generator, and a built-in printer option.

| Parameter | TM-35DV | TM-50DV |

|---|---|---|

| Chamber volume | 35L | 50L |

| Chamber size | Φ300×500mm | Φ340×550mm |

| Working pressure | 0.22Mpa | 0.22Mpa |

| Working temperature | 134℃ | 134℃ |

| Temperature adjust range | 105–134℃ | 105–134℃ |

| Timer range | 0–99min | 0–99min |

| Heat average | ≤±1℃ | ≤±1℃ |

| Power | AC220V 50Hz / 2.7KW | AC220V 50Hz / 2.7KW |

| Dimensions (mm) | 550×850×500 | 600×850×560 |

| Gross / Net weight | 113kg / 107kg | 125kg / 110kg |

If you want to compare configuration options (printer vs. digital records, chamber sizing, and cycle programming) against your instrument inventory and throughput targets, the most efficient approach is to map your top five loads (by frequency and complexity) to the validated cycles and loading diagrams. You can reference the full product overview here: Class B table-top pulse vacuum steam sterilizer specifications .

How to Evaluate a Supplier: Documentation, Serviceability, and Risk Control

Beyond chamber volume and cycle parameters, supplier capability is what keeps your sterilization program stable over years of use. As a manufacturer, we recommend assessing suppliers on serviceability and documentation as rigorously as on price.

- Validation support: clear guidance for Bowie-Dick/Helix/vacuum testing and how those results should be recorded and reviewed.

- Preventive maintenance plan: consumables, gasket inspection, cleaning intervals, and recommended calibration checks.

- Spare parts and uptime: availability of vacuum components, sensors, and door safety parts, plus documented response times.

- Training package: standardized loading diagrams, common alarms, and troubleshooting to reduce user-driven variation.

In summary, the best Class B autoclave decision is the one that matches your most complex load, verifies air removal and penetration routinely, and produces clean documentation. If you share your top instrument categories and daily throughput target, we can recommend an appropriate tabletop configuration and an implementation checklist aligned to your workflow.

ส่งจดหมายถึงเรา

ติดต่อเรา

+86-510-86270699

ความเป็นส่วนตัว

ข้อมูลในเว็บไซต์นี้มีไว้สำหรับประเทศและเขตอำนาจศาลนอกเขตสาธารณรัฐประชาชนจีนเท่านั้น

ความเป็นส่วนตัว

ข้อมูลในเว็บไซต์นี้มีไว้สำหรับประเทศและเขตอำนาจศาลนอกเขตสาธารณรัฐประชาชนจีนเท่านั้น

ความเป็นส่วนตัว

ความเป็นส่วนตัว