การค้นหาผลิตภัณฑ์

ภาษา

ออกจากเมนู

การทดสอบการกำจัดอากาศสำหรับหม้อนึ่งความดัน: วัตถุประสงค์ วิธีการ และคู่มือการปฏิบัติตามข้อกำหนด

โพสต์โดย ผู้ดูแลระบบ | 01 Oct

Air Removal Test for Autoclaves: What It Proves and Why It Matters

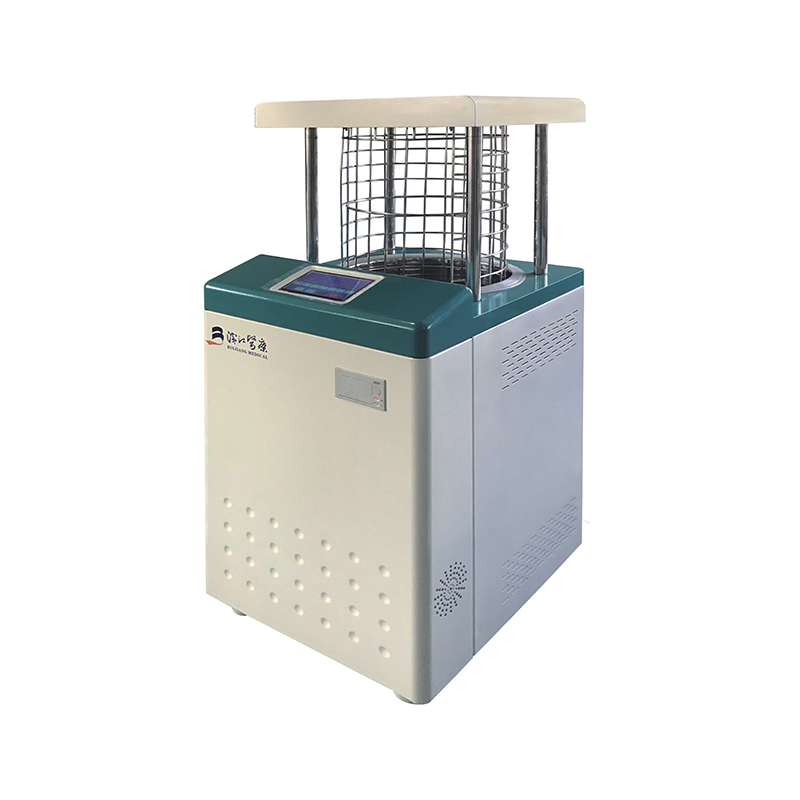

Effective steam sterilization depends on complete air removal. Residual air blocks steam penetration, creating cold spots that undermine microbial kill and raise patient and product risk. The air removal test verifies whether the autoclave’s vacuum system and steam injection can reliably purge air and achieve uniform, saturated steam conditions before the sterilization phase.

In practice, this test serves as a rapid, routine assurance of sterilizer performance, often performed daily before clinical or manufacturing loads. It is essential for pre-vacuum steam autoclaves used in healthcare, laboratories, pharmaceutical and device manufacturing.

Core Principles: Steam, Vacuum, and Air Entrapment

Steam sterilization requires saturated steam at a controlled temperature and pressure. Air acts as an insulator and lowers the partial pressure of steam, preventing proper heat transfer to load surfaces. The test challenges the autoclave’s ability to remove air via pre-vacuum pulses and to ensure steam is evenly distributed without leaks, blockages, or control faults.

- Residual air reduces sterilization efficacy by creating cold spots and uneven temperature profiles.

- Successful air removal yields uniform temperature and saturated steam, enabling reliable lethality (F 0 ).

- Pre-vacuum pulses and steam admission must be correctly sequenced and controlled to purge air from chamber and load.

Standard Methods: Bowie-Dick and Helix Tests

Two widely accepted methods assess air removal and steam penetration. Both are designed to detect faults in vacuum performance, steam quality, and leak-related air entrapment before processing real loads.

Bowie-Dick Test (Pack or Test Sheet)

The Bowie-Dick test uses a specialized pack or test sheet that reacts to steam penetration. It challenges the sterilizer with a standardized resistance, revealing incomplete air removal through non-uniform color change patterns.

- Run at 134°C for about 3.5 minutes in an empty chamber following recommended pre-vacuum pulses.

- Pass: uniform color change across the indicator field. Fail: patchy or incomplete change, edge-to-center gradients, or “blotches.”

- Daily use in hospital CSSDs and labs to verify air removal before routine loads.

Helix Test (Process Challenge Device)

A helix device uses a narrow-lumen tube with an indicator at the end, simulating the worst-case scenario for steam penetration into long, small-bore instruments. It is particularly relevant when sterilizing tubular devices.

- Run at the cycle’s setpoint (often 134°C). The indicator at the distal end must show complete change.

- Pass criteria mirror uniform indicator response; failures suggest air pocketing or insufficient pre-vacuum quality.

- Recommended for facilities processing lumen instruments to confirm penetration performance.

Step-by-Step: How to Perform the Air Removal Test

A consistent procedure ensures reliable results and early detection of performance drift. The steps below reflect common practice for pre-vacuum hospital and lab autoclaves.

Preparation

- Start with an empty, clean, and dry chamber. Verify drain and filter cleanliness.

- Confirm steam supply quality: dryness fraction, no non-condensable gases, proper pressure.

- Select the dedicated test cycle (Bowie-Dick or helix) from the autoclave program menu.

Execution

- Place the test pack or helix device in the chamber center on the lowest shelf unless manufacturer specifies otherwise.

- Run the cycle at the specified temperature and time (e.g., 134°C for 3.5 minutes for Bowie-Dick).

- Allow complete drying as instructed; remove and assess indicator immediately for uniformity.

Interpretation and Documentation

- Record pass/fail, date, operator, autoclave ID, cycle parameters, and any anomalies.

- Retain test sheets as part of quality records to support audits and traceability.

- Investigate and remediate failures before processing any clinical or production loads.

Common Failure Patterns and Practical Troubleshooting

Failure patterns on the indicator provide clues to root causes. Addressing them promptly prevents compromised sterilization and rework.

| Indicator Pattern | Likely Cause | Corrective Action |

| Patchy/uneven color | Residual air; weak vacuum | Leak test; service vacuum pump; check door seals |

| Edge-to-center gradient | Non-condensable gases; poor steam quality | Verify steam generator; purge lines; test dryness fraction |

| No change at distal helix end | Insufficient penetration into lumens | Increase pre-vacuum pulses; inspect PCD; confirm cycle parameters |

| Consistent failure after maintenance | Incorrect settings; sensor miscalibration | Recalibrate pressure/temperature; restore validated setpoints |

Compliance and Standards: What Auditors Expect

Regulators and standards bodies expect documented, routine air removal testing with clear criteria and traceable records. Aligning with recognized standards ensures consistent quality and defensibility of sterilization outcomes.

- EN 285 : Requirements for large steam sterilizers, including daily Bowie-Dick tests and leakage tests.

- ISO 17665 : Sterilization of health care products—moist heat; covers validation, routine control, and performance qualification.

- HTM/HTM (UK) Guidelines : Operational guidance for hospital sterilizers, detailing test frequencies and acceptance criteria.

- AAMI/ANSI ST79 : Comprehensive practice for steam sterilization in healthcare facilities, including air removal and process challenge devices.

Auditable elements include SOPs, training records, test logs, maintenance reports, deviation investigations, and documented acceptance criteria. Facilities should map local regulatory requirements to internal quality systems and maintain readiness for inspections.

Best Practices for Reliable Daily Checks

Consistency is the backbone of reliable sterilization. These practices help ensure your air removal tests reflect true performance and catch issues early.

- Run tests at the start of each shift and after maintenance or parameter changes.

- Standardize placement of test packs/devices and use manufacturer-approved products.

- Perform periodic leak tests to confirm chamber integrity.

- Monitor steam quality and condensate; correct non-condensable gas issues promptly.

- Train operators on interpreting indicator patterns and escalation steps.

Integrating Air Removal Tests into Validation and PQ

During IQ/OQ/PQ, air removal performance is verified under controlled conditions and worst-case loads. Routine air removal tests then serve as an ongoing check that validated performance remains intact.

Link routine test outcomes to preventive maintenance schedules and deviation management. Persistent failures should trigger root-cause analysis, revalidation, and potential suspension of sterilization activities until resolution.

Key Takeaways and Quick Reference

Air removal tests verify the autoclave’s ability to eliminate residual air and ensure uniform steam penetration—critical to sterilization efficacy and regulatory compliance. Use Bowie-Dick or helix methods daily, document results rigorously, and act swiftly on failures with structured troubleshooting.

| Test Type | When to Use | Pass Criteria |

| Bowie-Dick | Daily on pre-vacuum sterilizers | Uniform indicator change |

| Helix PCD | When processing lumen devices | Full change at distal end |

ส่งจดหมายถึงเรา

ติดต่อเรา

+86-510-86270699

ความเป็นส่วนตัว

ข้อมูลในเว็บไซต์นี้มีไว้สำหรับประเทศและเขตอำนาจศาลนอกเขตสาธารณรัฐประชาชนจีนเท่านั้น

ความเป็นส่วนตัว

ข้อมูลในเว็บไซต์นี้มีไว้สำหรับประเทศและเขตอำนาจศาลนอกเขตสาธารณรัฐประชาชนจีนเท่านั้น

ความเป็นส่วนตัว

ความเป็นส่วนตัว