การค้นหาผลิตภัณฑ์

ภาษา

ออกจากเมนู

การแทนที่ด้วยแรงโน้มถ่วงช่วยเพิ่มความน่าเชื่อถือของเครื่องนึ่งขวดนมแนวนอนได้อย่างไร

โพสต์โดย ผู้ดูแลระบบ | 24 Jul

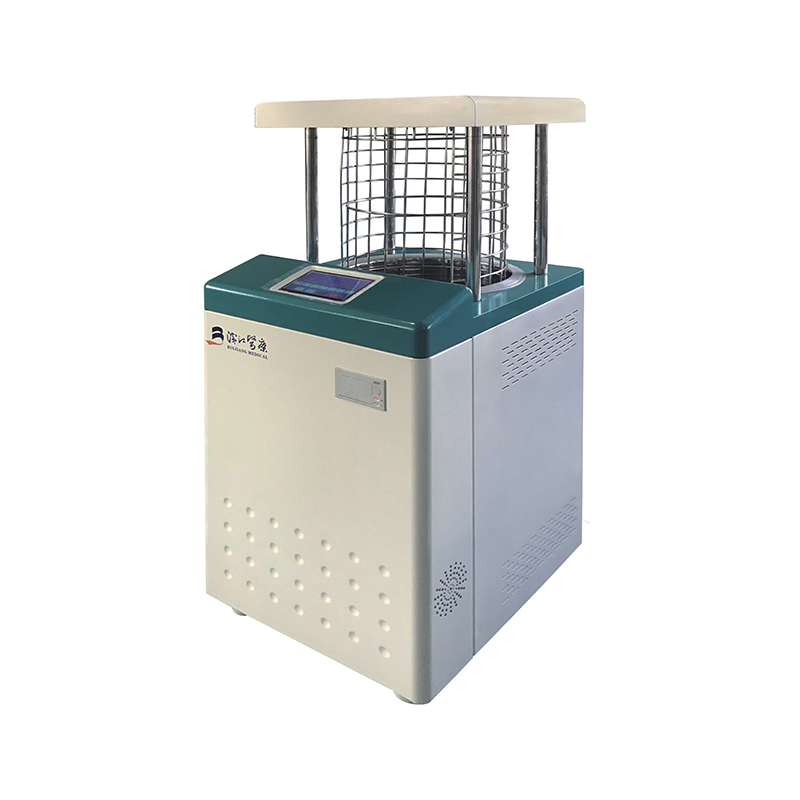

Gravity Displacement: The Core Mechanism Behind Reliable Horizontal Steam Sterilization

Gravity displacement is the foundational air-removal method in horizontal pressure steam sterilizers. By leveraging the density difference between steam and air, saturated steam pushes residual air out of the chamber, ensuring uniform heat transfer across instruments and packaging. This simple physics-driven approach elevates reliability by reducing air pockets, stabilizing sterilization conditions, and improving cycle reproducibility.

How Gravity Displacement Improves Air Removal and Steam Penetration

In gravity displacement cycles, steam introduced at the chamber’s top displaces denser air downward through the drain. The continuous purge of air prevents insulating layers that impede heat transfer. As a result, wrapped packs, lumen-free instruments, and porous loads receive consistent contact with saturated steam, accelerating temperature rise to the target setpoint and minimizing cold spots.

- Enhanced steam contact: Air removal enables saturated steam to condense on surfaces, releasing latent heat efficiently.

- Uniform temperature distribution: Reduced stratification lowers variability across shelves in horizontal chambers.

- Lower risk of failed cycles: Eliminating trapped air curbs incomplete sterilization due to inadequate exposure.

Cycle Control: Pressure, Temperature, and Hold Time Consistency

Reliable sterilization depends on reaching and holding the correct combination of pressure and temperature for the validated exposure time. Gravity displacement stabilizes these parameters by quickly evacuating air, which otherwise dampens pressure readings and delays temperature equilibration. Once air is purged, the chamber behaves predictably, allowing precise control over the holding phase and consistent lethality (F 0 ).

- Faster approach to setpoint: Less air means less thermal inertia and quicker steam saturation.

- Accurate pressure feedback: Pressure correlates better with steam temperature without air dilution.

- Stable holding phase: Uniform conditions maintain targeted exposure for validated cycle lethality.

Load Configuration Best Practices in Horizontal Chambers

Because horizontal sterilizers can be more prone to air layering, load arrangement is critical. Proper spacing and orientation allow gravity-driven steam flow to sweep air out effectively. Use compatible packaging and avoid obstructing the drain path to preserve the displacement effect.

- Leave gaps between packs and trays to permit steam circulation and air escape.

- Position heavier items lower, keeping the drain path clear at the chamber base.

- Do not stack fabric packs tightly; allow pathways for steam ingress and condensate egress.

- Use validated wraps and pouches with adequate permeability to saturated steam.

Comparing Gravity Displacement and Vacuum-Assisted Cycles

While pre-vacuum cycles actively remove air with mechanical pumps, gravity displacement uses passive density differences. For many instrument sets and routine hospital CSSD loads, gravity cycles offer robust reliability when properly configured. Pre-vacuum may be preferred for dense, highly wrapped, or lumened items. Understanding the trade-offs helps align cycle choice with load characteristics.

| Aspect | Gravity Displacement | Pre-Vacuum |

| Air Removal Method | Passive displacement via steam | Active vacuum pumping |

| Best For | Unwrapped, simple packs, porous loads | Wrapped, dense sets, lumened devices |

| Reliability Drivers | Correct loading, drain clearance | Vacuum integrity, leak testing |

| Cycle Complexity | Lower—simpler control scheme | Higher—pump, leak tests, pulsed vac |

In practice, gravity displacement remains a dependable choice for many horizontal chamber applications, provided loads match the cycle’s air-removal capability and the device is maintained.

Instrumentation and Monitoring for Reliability Assurance

Monitoring validates that gravity displacement achieved the intended sterilization conditions. Combine physical measurements with chemical and biological indicators to confirm air removal and steam penetration within the load.

- Thermocouples or data loggers placed at worst-case locations to track chamber and load temperatures.

- Chemical integrators inside packs to detect adequate exposure to saturated steam.

- Biological indicators for periodic validation, focusing on difficult-to-penetrate areas.

- Drain temperature and condensate checks to verify continuous air purge during the come-up phase.

Maintenance and Process Controls that Sustain Performance

Reliability hinges on chamber integrity and consistent steam quality. Routine inspection prevents air leaks and flow restrictions that undermine gravity displacement. Documented process controls sustain cycle performance across shifts and workloads.

- Regular gasket and door seal checks to prevent air ingress.

- Drain line cleaning and strainer maintenance to keep displacement efficient.

- Steam quality verification: dryness fraction, non-condensable gases, and superheat limits.

- Cycle parameter audits: pressure ramps, exposure time, and cooldown profiles.

- Load configuration SOPs and staff training to reduce variability.

Troubleshooting Common Reliability Issues

When gravity displacement performance dips, symptoms often point to air management problems or steam quality. Targeted checks isolate root causes and restore consistent lethality.

- Persistent chemical indicator failures: verify drain obstruction, load density, and wrap permeability.

- Slow heat-up: investigate air leaks, inadequate steam supply, or excessive condensate.

- Uneven shelf temperatures: reassess spacing and avoid touching chamber walls with packs.

- Wet packs post-cycle: check drying phase, steam dryness, and overloading.

Key Takeaways for Horizontal Pressure Steam Sterilizers

Gravity displacement enhances sterilization reliability by removing insulating air, promoting saturated steam contact, and stabilizing cycle control. In horizontal chambers, its effectiveness depends on correct loading, unobstructed drains, sound seals, and verified steam quality. With appropriate monitoring and maintenance, gravity displacement delivers repeatable, high-confidence sterilization outcomes for a wide range of medical, laboratory, and industrial applications.

ส่งจดหมายถึงเรา

ติดต่อเรา

+86-510-86270699

ความเป็นส่วนตัว

ข้อมูลในเว็บไซต์นี้มีไว้สำหรับประเทศและเขตอำนาจศาลนอกเขตสาธารณรัฐประชาชนจีนเท่านั้น

ความเป็นส่วนตัว

ข้อมูลในเว็บไซต์นี้มีไว้สำหรับประเทศและเขตอำนาจศาลนอกเขตสาธารณรัฐประชาชนจีนเท่านั้น

ความเป็นส่วนตัว

ความเป็นส่วนตัว